XGN2 3.6KV 7.2KV 12KV 630-2500A

Indoor Box-Type Fixed Metal Enclosed Switchgear

- Description

- Installation

XGN2-12 box-type fixed metal-enclosed switchgear (referred to as switchgear) is used for receiving and distributing electric energy in 3.6, 7.2, 12kv three-phase AC 50Hz systems, suitable for frequent operation occasions, and its busbar system is a single busbar (and can be derived single bus with bypass and double bus structure). The switchgear meets the requirements of the national standard GB3906-91 (3-35kv AC metal-enclosed switchgear) and the national standard IEC298, and has two proposed “five-proof” locking functions.

Product Description

XGN2-12 box-type fixed metal-enclosed

switchgear (referred to as switchgear) is used for receiving and distributing

electric energy in 3.6, 7.2, 12kv three-phase AC 50Hz systems, suitable for

frequent operation occasions, and its busbar system is a single busbar (and can

be derived single bus with bypass and double bus structure). The switchgear

meets the requirements of the national standard GB3906-91 (3-35kv AC

metal-enclosed switchgear) and the national standard IEC298, and has two

proposed "five-proof" locking functions.

The main switch of the switch cabinet adopts ZN28-12 series vacuum circuit

breaker, equipped with CDI7 series electromagnetic operating mechanism or CT19

series spring operating mechanism, and the isolating switch adopts GN30-12

rotary isolating switch or GN22-12 high current isolating switch series.

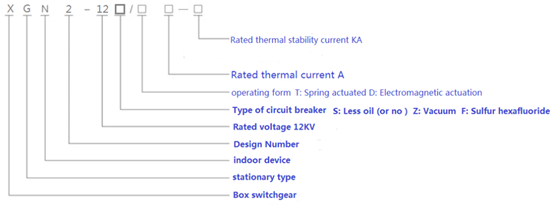

Model Description

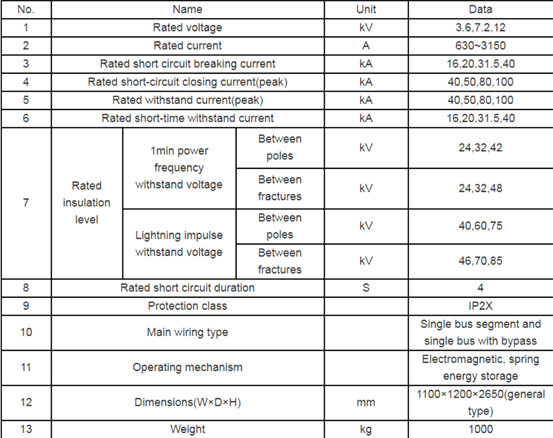

Product technical parameters and external dimensions

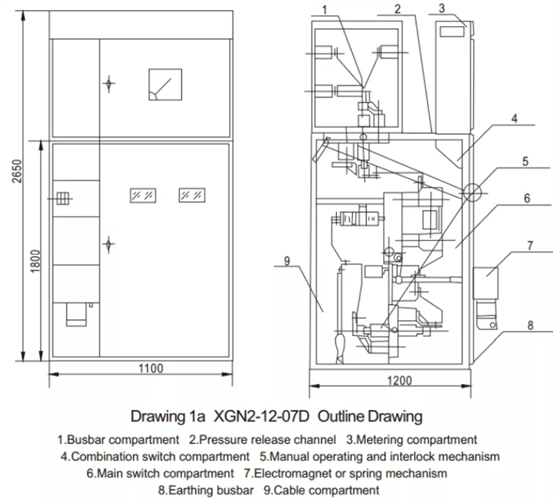

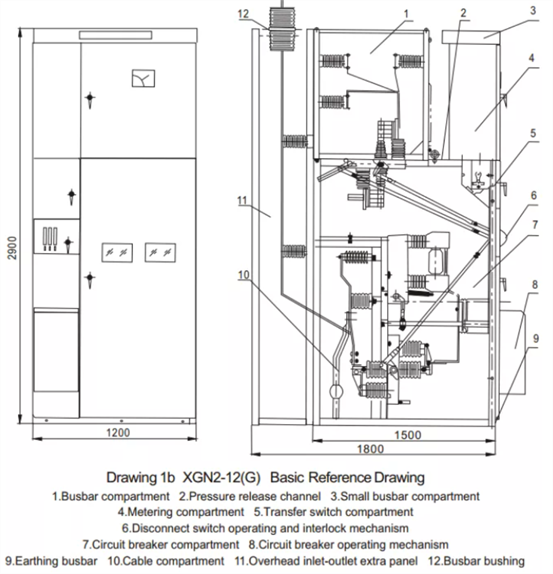

Product structure features

1: The switch cabinet is a metal closed box

structure, and the cabinet frame is welded with angle steel. The cabinet is

divided into circuit breaker room, bus room, cable room and relay room. The

interior is separated by steel plates.

2: The circuit breaker room is located at the lower part of the cabinet, and

the circuit breaker drive is connected by the pull rod and the operating

mechanism; the lower end of the circuit breaker is connected to the current

transformer, the current transformer is connected to the isolating switch

terminal, and the upper end of the circuit breaker is connected to the

isolating switch terminal. The circuit breaker room is also provided with a

pressure relief channel. If arcing occurs inside, the gas can be released

through the exhaust channel.

3: The busbar compartment is at the rear upper part of the cabinet. In order to

reduce the height of the cabinet, The busbar arrangement shape is 品, it is supported by a porcelain

insulator with a bending strength of 7350N, and the busbar is connected to the

upper isolating switch terminal.

4: The cable compartment is behind the lower part of the cabinet. The support

insulators in the cable compartment can be equipped with monitoring devices and

the cables are fixed on the brackets. The contact is the wiring communication

cable M of this room

5: The operating mechanism of the circuit breaker is installed at the lower

left, above which is the operating interlocking mechanism of the isolating

switch.

6: The switch cabinet is double-sided maintenance. In the front, the secondary

components of the relay room are inspected, the operating mechanism, mechanical

interlock and transmission parts are maintained, the circuit breaker is

inspected, and the upper busbar and cable terminals are repaired in the rear.

Lights are installed in the circuit breaker room and the cable room.

7:There is a grounding

copper bar parallel to the width of the cabinet below the front, and its

cross-section is 4*40mm². Mechanical interlock: prevent the on-load isolating

switch; prevent the circuit breaker from accidentally opening and closing;

prevent the grounding knife from closing.

Environment condition

1. Ambient air temperature: -5~+40 and the

average temperature should not exceed +35 in 24h.

2. Install and use indoors. Altitude above sea level for operation site should

not exceed 2000M.

3. Relative humidity should not exceed 50% at max temperature +40. Higher

relative humidity is allowed at lower temperature. Ex. 90% at +20. But in view

of the temperature change, it is possible that moderate dews will produce

casually.

4. Installation gradient not exceed 5.

5. Install in the places without fierce vibration and shock and the sites

insufficient to erode the electrical components.

6. Any specific requirement, consult with manufactory.

Request a Quote

We will deliver a solution and quote that best suits your business needs

- Hot Products

GTXGN 12KV 630A 1250A

High Voltage Solid Insulation Ring Network Cabinet HV Switchgear

Explore More

HXGN 12KV 630A

Box-Type Fixed Ring Network Switchgear Electric Control Cabinet Switch Control Cabinet

Explore More

XGN66 3.6KV 7.2KV 12KV 630A 1250A

Fixed Box Type High Voltage Switchgear Control Equipment

Explore More